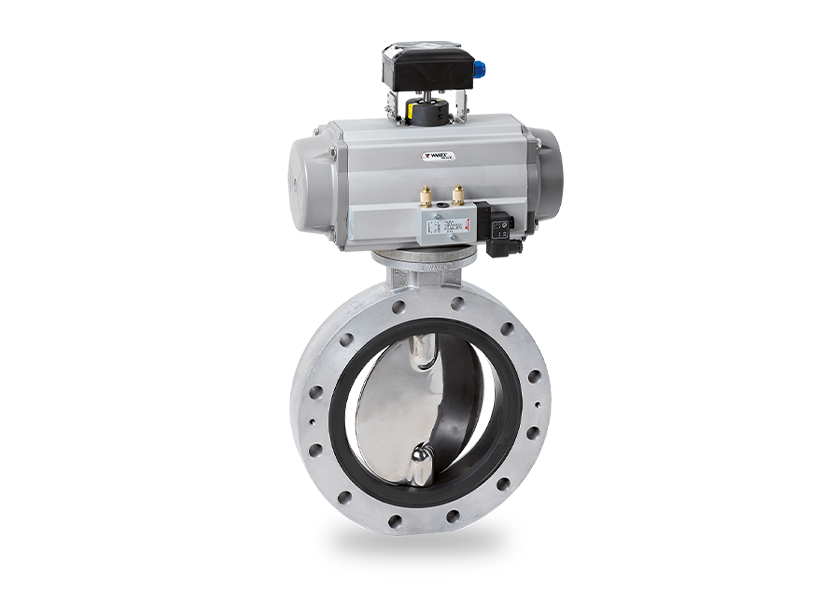

DKZ 103 GS

Vanne-papillon avec certificat d‘épreuve DMT de résistance au choc d‘explosion et d‘arrêt de la propagation de flamme.

- Diamétres nominaux : DN 50 – DN 500

- Plage de températures : – 10°C à + 60°C*

- Résistance au choc d‘explosion : jusqu‘à 10 bar*

- Manchette d‘étanchéité : remplaçable ou fixe vulcanisée

- Exécution suivant examen de Type BVS03AtexH023X

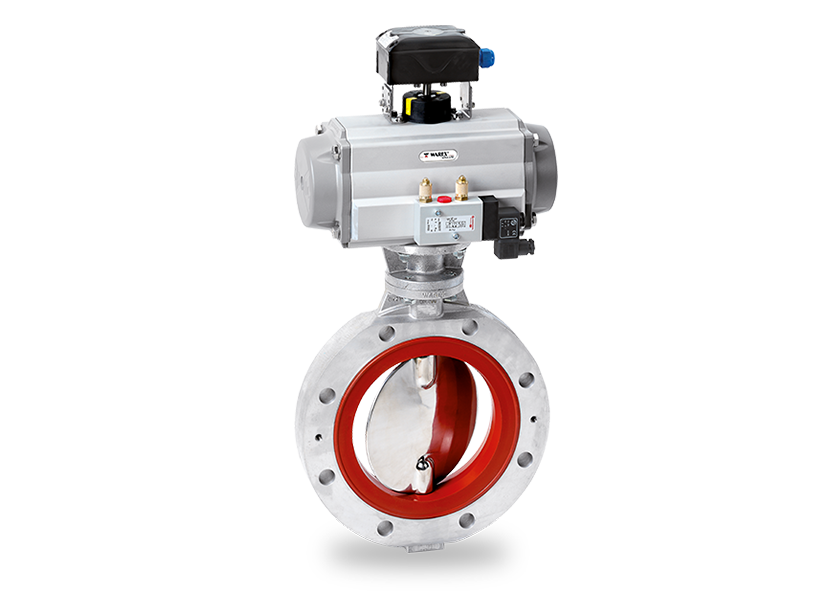

Vanne-papillon avec certificat d‘épreuve DMT de résistance au choc d‘explosion et d‘arrêt de la propagation de flamme.

- Diamétres nominaux : DN 50 – DN 200

- Plage de températures : – 10°C à + 150°C*

- Résistance au choc d‘explosion : jusqu‘à 14 bar*

- Manchette d‘étanchéité : remplaçable ou fixe vulcanisée

- Exécution suivant examen de Type BVS07AtexH065X

* Les limites d‘application dépendent toujours du dia – mètre nominal, de la température, de la combinaison des matières. Les paramètres déterminants sont ceux qui sont spécifiés dans la commande.

SALONS

POWTECH 2019 09. – 11.04.2019

VRAC TECH-BULK TECH 2019

ACTUALITÉS

Site Web

Notre nouveau site internet