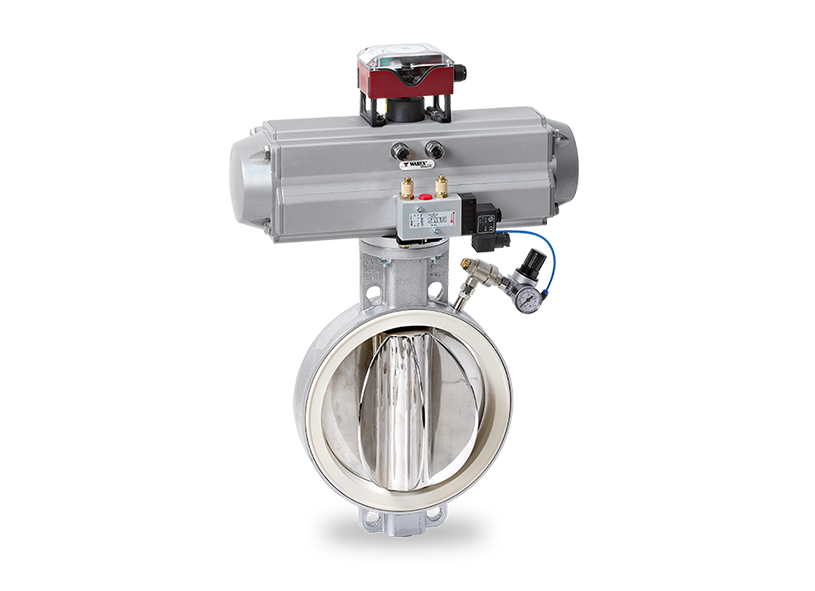

Rotary Valve DKZ 103/110 APS®

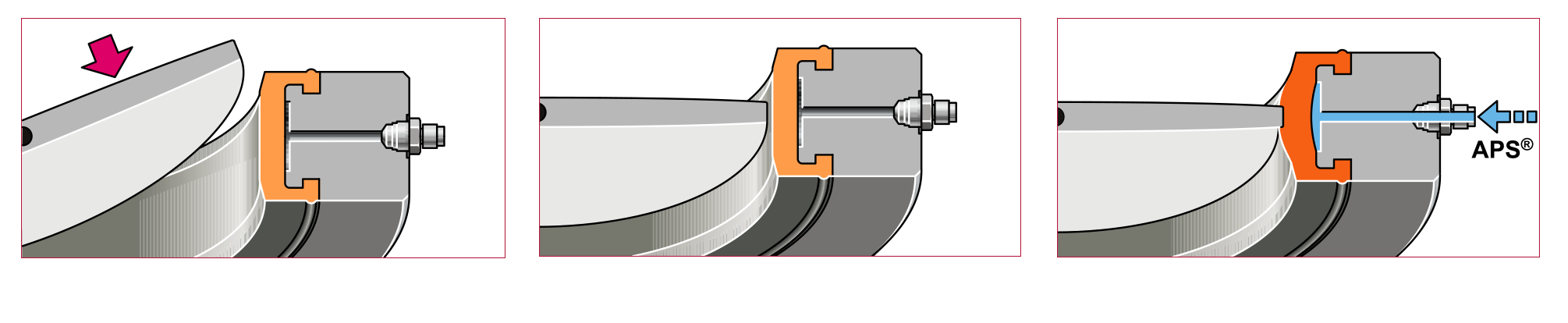

Basis of the Rotary Valves are the over many years proved Shut-Off Valves of the centric APS® class. They can be used for charging and blocking. The APS® construction indicates that the sealing element is pressed pneumatically to the perimeter of the disk in position “closed”! A steady pressure tightness is still guaranteed with slight wears by the constant contact pressure of the sealing element of the Flap Valve. Therefore it shows a special suitability for abrasive bulk material. The Shut-Off Valve can be employed depending on the used sealing material in a temperature range of – 40°C up to + 200°C. For the triggering of the pneumatic seal Warex offers different solutions in which the seal can, if necessary, deflated with vacuum support or be charged with nitrogen.

* Operational limitations depend on nominal width, temperature and composite materials. Crucial are the parameters set in the confirmation.

EXHIBITION DATES

SOLIDS EASYFAIRS Dortmund

16. – 17.06.2021

NEWS

Website

Our new Website