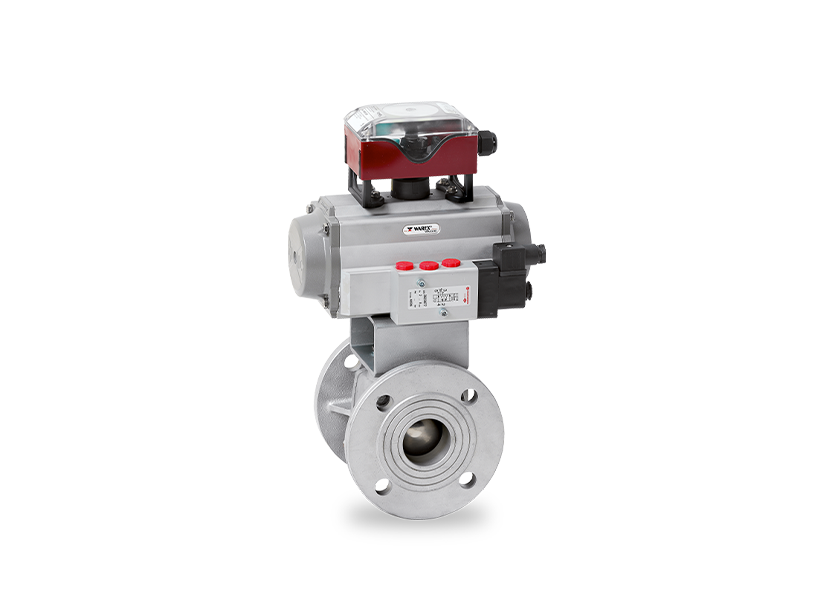

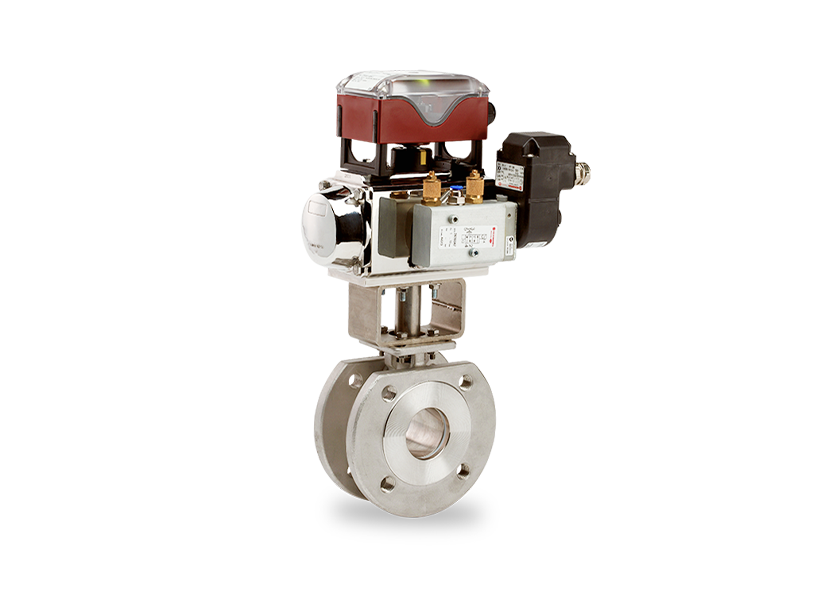

DBV 140 F

Compact Ball Valve with flange connection, full bore up to DN 100,

from DN 125 with reduced bore, standard in anti static design.

- Range of Nominal Widths: DN 15 – DN 200

- Operating Temperature: – 10°C to + 200°C *

- Differential pressure: up to 16 bar *

- sealing: PTFE / FPM-O-Rings

- body: WCB or stainless steel 1.4408

- ball: stainless steel 1.4401

* Operational limitations depend on nominal width, temperature and composite materials. Crucial are the parameters set in the confirmation.

EXHIBITION DATES

SOLIDS EASYFAIRS Dortmund

16. – 17.06.2021

NEWS

Website

Our new Website