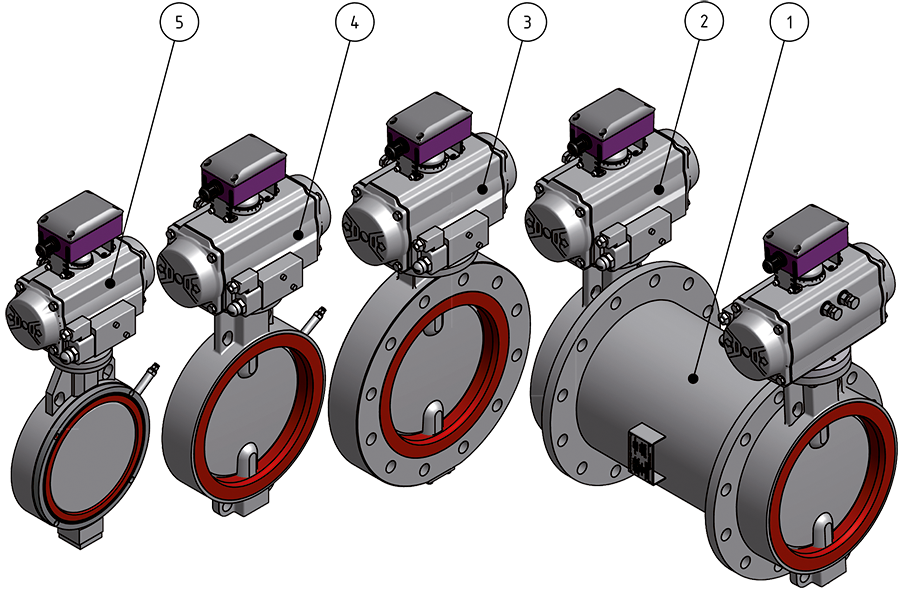

DTS

For discharging and dosing of bulk materials from silos, storage bins, sifters, filters, cyclones, etc.

- Range of Nominal Widths: DN 50 – DN 600

- Chamber volume: 0,5 ltr. – 300 ltr.

- Connection: PN 6 – PN 16, ANSI 150 lbs.

- Lock operations: max. 10 / min., depends on nominal width

- Dosing weighers, bagging lines, etc.

- Systems where abrasive media is discharged or dosed,

in which a gas-tight shut-off is required

* Operational limitations depend on nominal width, temperature and composite materials. Crucial are the parameters set in the confirmation.

EXHIBITION DATES

SOLIDS EASYFAIRS Dortmund

16. – 17.06.2021

NEWS

Website

Our new Website