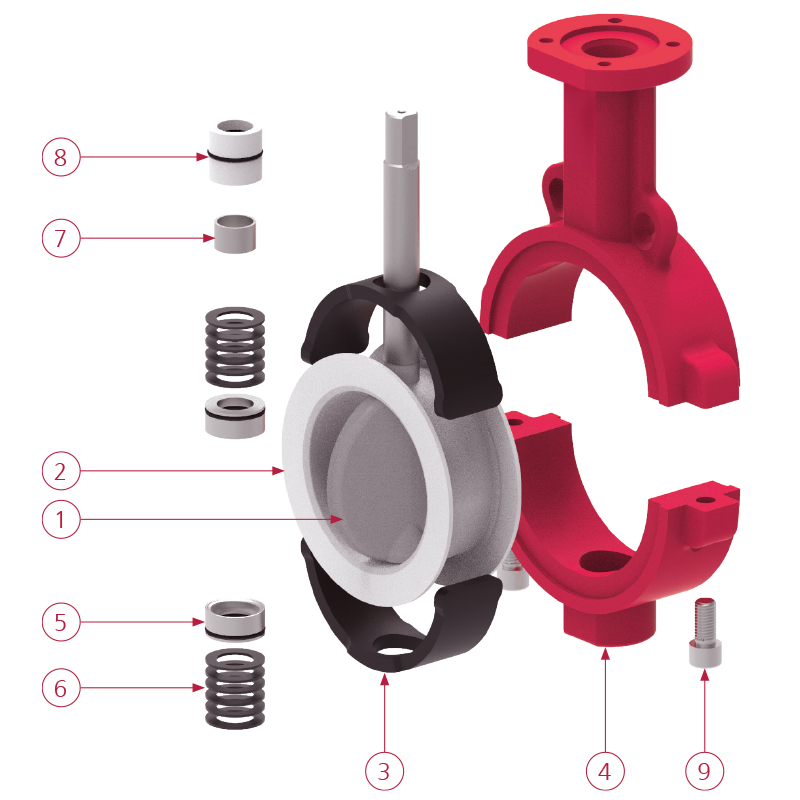

chemflyer | CST

PTFE-lined butterfly valve for use with aggressive media.

- Nominal size range: DN 250 – DN 1200 / 1″ – 48″

- Flange connection:

EN 1092-1, PN 10-16

ASME B16.5, Class 150

JIS 10K - Maximum working pressure:

DN 25-450: 10 bar

DN 500-600: 6 bar

DN 650-1200: 3 bar - Operating temperature: – 20°C bis + 200°C*

- Face-to-face dimension: EN 558, Grundreihe 1

- Disc materials:

PFA / PFAc, PFA konduktiv / Edelstahl, 1.4404

/ Duplex, 1.4462, 1.4469 / Titanium Grade 2, 3.7035

/ Hastelloy C, 2.4602, 2.4819 - Seat ring materials:

PTFE / modifiziertes PTFE / modifiziertes PTFE konduktiv

/ UHMPE - Insert materials:

Silikon / EPDM / FKM - Housing materials:

Sphäroguss, 5.3103 / Edelstahl, 1.4404 / Carbonstahl

/ Kunststoff, VE-CF - Conformity:

DGRL 2014/68/EU / ATEX 2014/34/EU

/ Lebensmittel (EG) Nr. 1935/2004, FDA

/ TA-Luft, ISO 15848-1 - Pressure test:

EN 12266-1

* Operational limitations depend on nominal width, temperature and composite materials. Crucial are the parameters set in the confirmation.

EXHIBITION DATES

SOLIDS EASYFAIRS Dortmund

16. – 17.06.2021

NEWS

Website

Our new Website